Automatic assembly devices

To optimize the application cycle time of die-cut parts, Adhex developed cutting-edge means, transitioning from non-ergonnomic manual process to automated, ensuring both efficiency and safety.

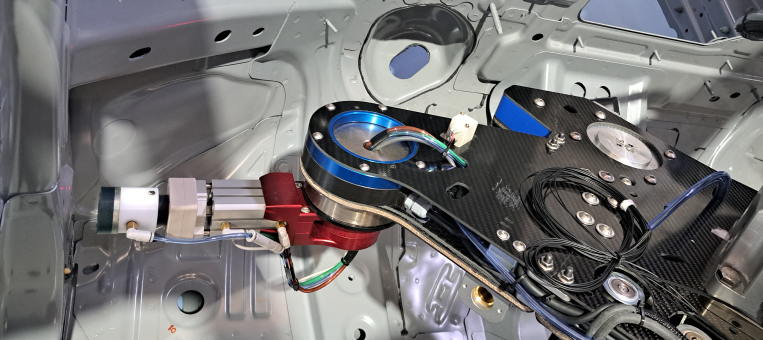

During car body production, over 100 holes are required for the e-coating process. These holes must subsequently be covered for corrosion, acoustic, and sealing purposes. Traditionally, this operation involves manual, time-consuming, and non-ergonomic processes. In response, Adhex has developed a range of adhesive patches that are easier to apply than current plastic plugs. These patches can be automated using state-of-the-art automatic application solutions, ensuring fast, precise, and fully controlled application of adhesive die-cut parts. Designed for application from both the interior and exterior of vehicles, our applicators seamlessly integrate into automotive production lines. As specialists in custom solutions, Adhex assists clients in tailoring these tools to meet their specific requirements.

Our range of automatic assembly devices

Discover other applications in the automotive die-cut adhesive parts segment

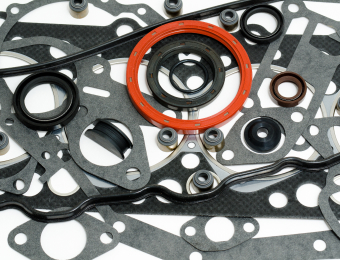

Hole covering & adhesive sealing elements of car body

In order to guarantee the tightness of the vehicle - against water, air, dust and noises, Adhex offers a range of resistant and durable gaskets that can be positioned outside as well as in the passenger compartment or engine block.

Protective die-cut adhesive parts

Air, water, dust, bad weather and thermal variations, vibrations and shocks: Adhex protects every vehicle thanks to its wide range of die-cut adhesive parts.

Die-cut adhesive parts for acoustic protection of vehicles

Adhex develops for vehicle manufacturers a range of adhesive parts contributing to sound insulation and absorption to contribute to a quieter drive.