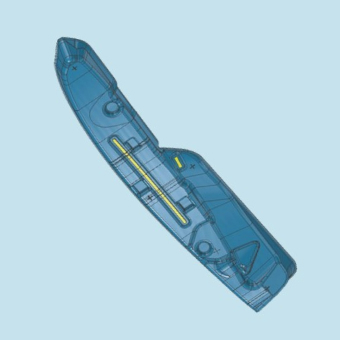

FA3_FOP270-3_HBPP_AF

Adhesive foam 270 for sound insulation

- Carrier: Black polyolefin foam

- Adhesive: Elastomeric hot melt foamed adhesive bead

- Liner: Brown non-stick paper

En savoir plus

→

Dimensions

- Size, shape and adhesive coating of the part specifically adapted to the car design requirements (system environment)

→

Usages

- Sound insulation for fender

- The part shape and the bead adhesive glue track is specially designed and adapted to avoid any risk of interfacing with fender environment

→

Bénéfices

- Lightness of the solution

- Easy to assemble

- Any kind of fixation on the vehicle available (clip, clamping, adhesive)

- Possible to adjust the raw characteristics material (density, thickness) in function to acoustic objective

- Area between the wing and the door fully closed

→

Stockage et durée de conservation

- 6 months from the date of production when the product is stored in his original packaging at 20°C (±5°C) and a relative humidity of approximately 50% (±15%). The products must be protected from temperatures above 40°C, UV light and relative humidity above 80%.

Découvrez d'autres produits de la gamme

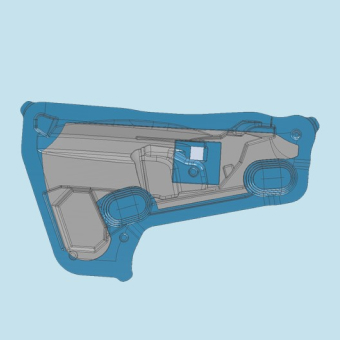

TA3_FOP100-2.2_HBPP_AP400

Acoustic adhesive foam 100 door water shield

- Acoustic patch: Adhesive acoustic fiber of 400g/sqm (Adhex XL Pad 400)

- Carrier: White polyolefin foam

- Adhesive: Elastomeric hot melt foamed adhesive bead

- Liner: Brown non-stick paper

- Integration of sound absorption patch (400g/sqm)

- Ideal lightweight solution for perfect water, air and dust tightness

- Bonding on painted sheet metal, plastic smooth or grained PP parts

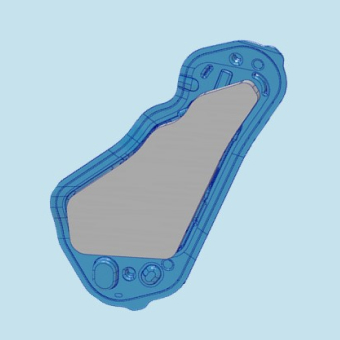

FA3_FOE900-3_HBPP_AP530VI

Acoustic adhesive foam 900 door water shield

- Acoustic patch: Adhesive acoustic fiber of 530g/sqm (Adhex XL Pad 600)

- Damping patch (anti-vibration): Heavy adhesive mass of 7,5kg/sqm (IFF)

- Carrier: Grey polyolefin foam

- Adhesive: Elastomeric hot melt foamed adhesive bead

- Liner: Brown non-stick paper

- Excellent acoustic level (hifi version)

- Integration of sound absorbing and anti-vibration patch

- Excellent acoustic performance (insulating solution 900g/sqm)

- Bonding on painted sheet metal, plastic smooth or grained PP parts

TA3_FOE900-3_HBPP_AC900

Acoustic adhesive foam 900 door water shield

- Acoustic patch: Adhesive acoustic cotton felt of 900g/sqm (Adhex XL Drypad 900)

- Carrier: Grey polyolefin foam

- Adhesive: Elastomeric hot melt foamed adhesive bead

- Liner: Brown non-stick paper

- Excellent acoustic level (hifi version)

- Integration of sound absorption patch in dry area

- Excellent acoustic performance (insulating solution 900g/sqm)

- Bonding on painted sheet metal, plastic smooth or grained PP parts